About Us

About Platinum Cross

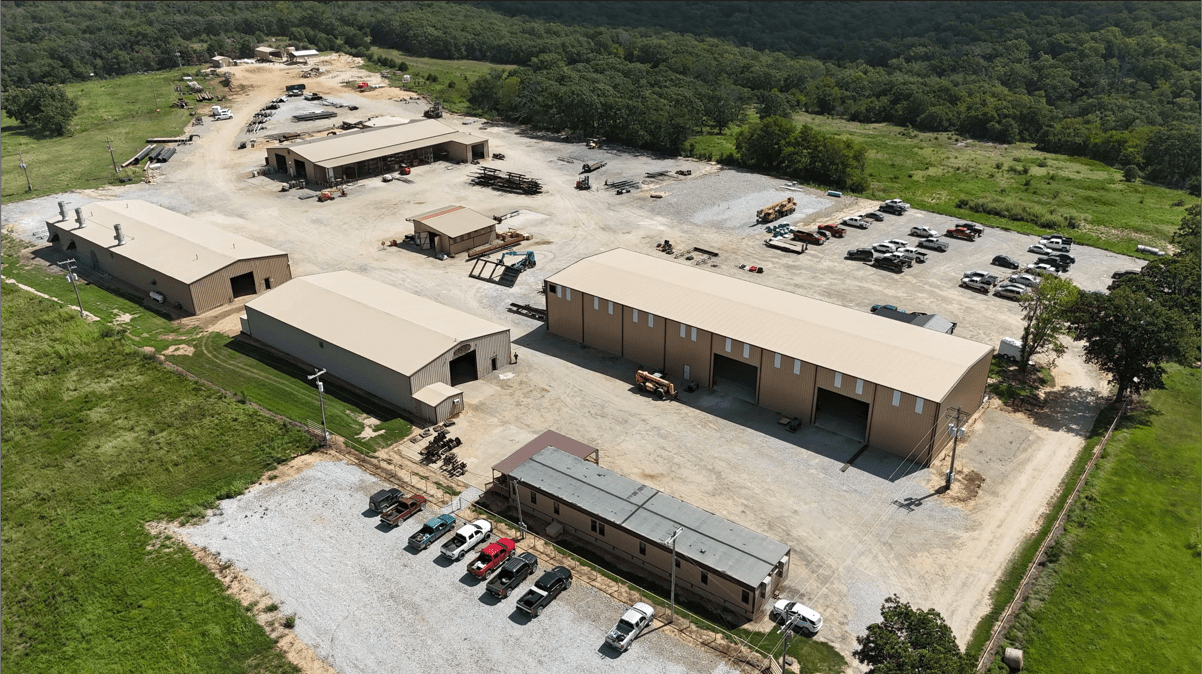

PCW was originally known as a piping fabricator that mass produced pig traps for the midstream sector for the one of the biggest Natural Gas producers. Now, PCW has grown to become an ASME vessel shop capable of taking on many types of projects for several different industries.

Throughout the last two years it has been goal to become diversified where our team can take on many different types of projects and successfully complete them without losing sight on our safety record and quality standards.

Our specialty is designing and building modular compressor stations, building all types of ASME vessels, being able to take on capital piping projects, and providing structural fabrication needs for all of the above.

Our goals for the future are to utilize our ASME U/S/R stamp by building more ASME vessels and utilizing our S stamp for taking on specialty piping projects.

Service Capabilities

At PC Welding, we offer a comprehensive range of capabilities to meet your industrial needs. Our facility and experienced staff ensure that every project, from fabrication to coatings, is completed with the utmost quality and efficiency.

Lifting Capacity:

- Indoor Lifting Capacity: 100,000 lbs

- Rental equipment available for lifting up to 160,000 lbs

- Outdoor Lifting Capacity: 75,000 lbs

- Mobile crane rental available for lifting up to 160,000 lbs

Facility Dimensions:

- Indoor Shop Dimensions: 20' W x 90' L x 20' H

- Over 55,000 sq ft of shop floor space

Coating Capabilities:

- All coatings are completed onsite

- Internal coating of vessels completed onsite

- Internal coating of pipe: Sub-contractor available within a 60-mile radius

- Hot dip galvanizing: Sub-contractor available within a 60-mile radius

Engineering and Certifications:

- Design and process engineering staff

- Certified Welding Inspector (C.W.I.) and NACE Level 1 certifications

- OSHA certified

Additional Services:

- Instrumentation and electrical services

- Heat tracing and insulation

- PWHT (Post Weld Heat Treatment) oven available within a 60-mile radius

- Localized PWHT performed at our facility

- NDE (Non-Destructive Examination) auto-processing room (American Piping Inspection)

- All torquing and hydro testing completed onsite

Shipping Capabilities:

- Shipping Capacity: 20' W x 100' L x 16' H, up to 160,000 lbs

Certifications and Material Capabilities:

- ASME and API 1104 Welding Procedure Specifications (WPS)

- Material capabilities include: Low temp carbon steel (CS), stainless steel (SS), 1.25 chrome (CH), 2.25 chrome (CH), 9 chrome (CH), and Inconel

Equipment:

- 6' x 20' x 2" thick CNC plasma table

- Regular and oversized semi-hauling available