Repairs & Alterations

At Platinum Cross Welding (PCW), we specialize in ASME-certified pressure vessel repair services, ensuring your equipment is restored to safe, compliant, and optimal working condition. Our team is certified to handle vessel repairs, alterations, and re-ratings under National Board "R" Stamp regulations, delivering high-quality solutions that meet the latest ASME code requirements.

With our 24/7 Emergency Response Team, we provide on-site and in-shop pressure vessel repairs to minimize downtime and get your operations back online quickly. Whether you need structural repairs, nozzle modifications, re-ratings, or ASME code compliance updates, PCW has the expertise and certifications to handle the job safely and efficiently.

Comprehensive Pressure Vessel Repair & Alteration Services

Our Key Services Include:

- Pressure Vessel Repairs & Re-Rating – Ensuring your vessel complies with the latest ASME edition, allowing continued safe operation.

- Emergency Pressure Vessel Repair – Our 24/7 response team minimizes plant downtime with rapid repair services.

- Nozzle Additions & Modifications – Enhancing your vessel’s functionality and operational efficiency.

- Crack Repairs & Weld Restorations – Certified welding repairs to restore vessel integrity and prevent safety hazards.

- Corrosion & Thickness Assessments – Non-destructive testing (NDT) and thickness inspections to evaluate vessel condition.

- Heat Exchanger & Separator Repairs – Complete component rebuilding, retubing, and pressure part repairs.

- Structural Reinforcements & Alterations – Strengthening vessels to handle increased pressure loads and operational changes.

- Hydrostatic & Pneumatic Testing – Ensuring repaired vessels meet ASME, API, and National Board standards.

Each repair and alteration project follows strict ASME code requirements, guaranteeing safe and durable pressure vessel restoration.

ASME "R" Stamp Certified Pressure Vessel Repairs

At Platinum Cross Welding, we take compliance and safety seriously. Our certifications and quality control measures ensure that every pressure vessel repair and alteration meets or exceeds industry standards.

- National Board "R" Stamp Certified – Authorized to repair and alter pressure vessels per National Board Inspection Code (NBIC) requirements.

- ASME-Compliant Welding & Fabrication – Expert welding repairs and component modifications under ASME Boiler & Pressure Vessel Code (BPVC).

- Certified Welding Inspectors (CWI) Onsite – Ensuring all repairs meet quality and safety guidelines.

- NACE Inspector Onsite – Providing corrosion control and protective coatings expertise for pressure vessel longevity.

- ASNT Level II Radiography & Non-Destructive Testing (NDT) – Offering comprehensive vessel inspections for structural integrity and compliance.

- OSHA-Trained Supervisors – Prioritizing workplace safety and environmental compliance during all repair operations.

With our certified team and rigorous safety protocols, we ensure that every repaired vessel is returned to service in peak operational condition.

Industries We Serve

We provide pressure vessel repair and alteration services for a wide range of industrial applications, including:

- Oil & Gas Refining & Processing – Vessel repairs for separators, dehydrators, scrubbers, and heat exchangers.

- Chemical & Petrochemical Facilities – Corrosion-resistant repairs and re-ratings for high-pressure chemical processing equipment.

- Power Generation & Energy Plants – Code-compliant repairs and reinforcement for boiler pressure vessels and steam systems.

- Manufacturing & Industrial Processing – Enhancing the longevity and efficiency of process vessels and pressure tanks.

- Food & Beverage Processing – Sanitary vessel repair and maintenance for food production facilities.

Service Areas: Trusted Pressure Vessel Repair Services Across Multiple States

With our central fabrication and repair facility in Okemah, OK, we serve clients across Oklahoma and neighboring states, including:

- Oklahoma (Tulsa, Oklahoma City, Norman, Stillwater, Lawton, and more)

- Texas (West Texas, South Texas, Houston, Dallas, and surrounding areas)

- Louisiana (Shreveport, Baton Rouge, Lafayette, New Orleans, and industrial hubs)

- Wyoming (Casper, Cheyenne, Gillette, and energy sectors)

- North Dakota (Bismarck, Williston, Minot, and Bakken oil fields)

- South Dakota (Sioux Falls, Rapid City, and surrounding regions)

- Nebraska (Omaha, Lincoln, Grand Island, and industrial centers)

We provide on-site pressure vessel repairs or in-shop restoration services, ensuring your equipment is back in operation quickly and safely.

Why Choose Platinum Cross Welding for Pressure Vessel Repairs?

- 24/7 Emergency Response Team – We minimize downtime with fast, reliable pressure vessel repairs.

- National Board "R" Stamp Certified – Ensuring compliance with all ASME and National Board repair standards.

- Highly Skilled Welding & Repair Experts – Our team consists of certified welders, inspectors, and fabricators.

- Strict Quality Control & Compliance – Every repair undergoes thorough testing and verification before returning to service.

- Cost-Effective & Long-Lasting Solutions – Our repairs extend the life of your pressure vessels, helping you avoid costly replacements.

Get a Quote for ASME-Certified Pressure Vessel Repair Services

Need emergency repairs, vessel re-ratings, or ASME-certified alterations? Platinum Cross Welding is your trusted partner for high-quality pressure vessel repair and modification services.

- 📞 Call us at: 918.998.7969

Let’s discuss your pressure vessel repair needs and find the best solution to get your equipment back in operation safely.

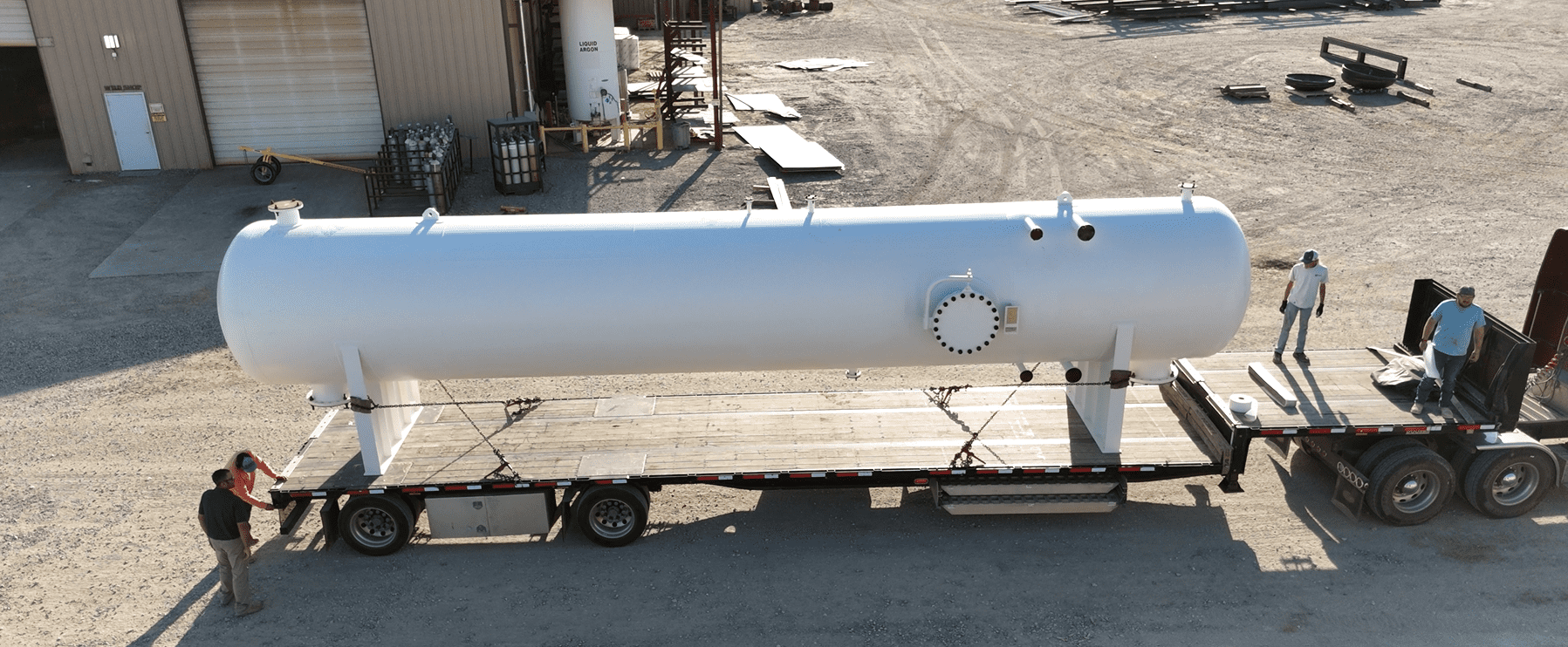

Repairs & Alterations Gallery

Certifications

- American Welding Society (AWS)

- Certified Welding Inspector (CW) Specialists

- American Society for Nondestructive Testing (ASNT) Level II Radiographer

- OSHA Trained Supervisors